If you are involved with the aerospace industry, or you are working in the automotive industry, then you will probably have heard of Precision Engineering. However, what is it and how important is it to the aerospace industry? This article will provide a basic overview of this term, and hopefully help you answer this question for yourself.

What Is Precision Engineering?

As the name suggests, Precision Engineering is an engineering field that has to do with precision in the manufacturing process of products. The definition of this term is somewhat vague as well. In simple terms, the engineers try to find ways to increase the level of precision in the manufacturing process so that their products are both durable and reliable.

They also try to reduce the level of variation and quality degradation, thereby ensuring that their products are sold for a longer period of time. Organisations such as Glacier energy services are amongst some of the main leaders in precision engineering, in the UK.

How Is Precision Engineering Conducted?

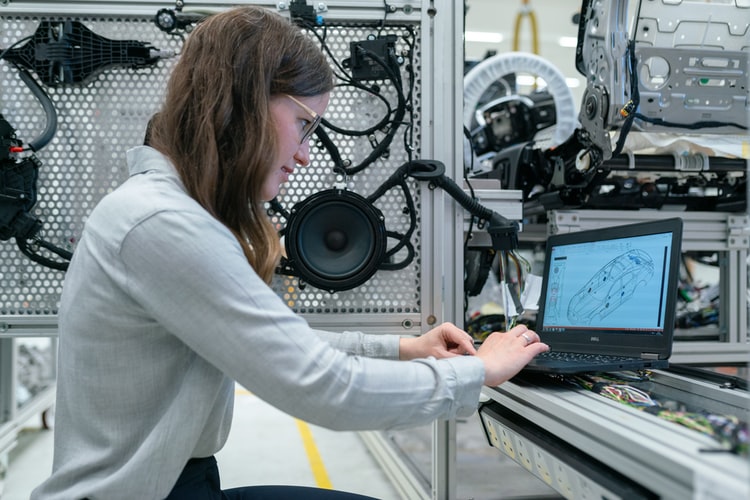

There are several other reasons that engineering companies choose to use this term in their products. The first is that it is very important for them to ensure that they get the precise design and specifications for their products, which is important in the aerospace industry, for example. This means that they must be able to create prototypes of their products and then try to get them to pass the specifications and standards, so that they can be sold.

Engineers also need to look after the quality of their products. After all, there is nothing worse than buying a product that does not work right when it is delivered to you. So engineers need to ensure that their products are durable and reliable.

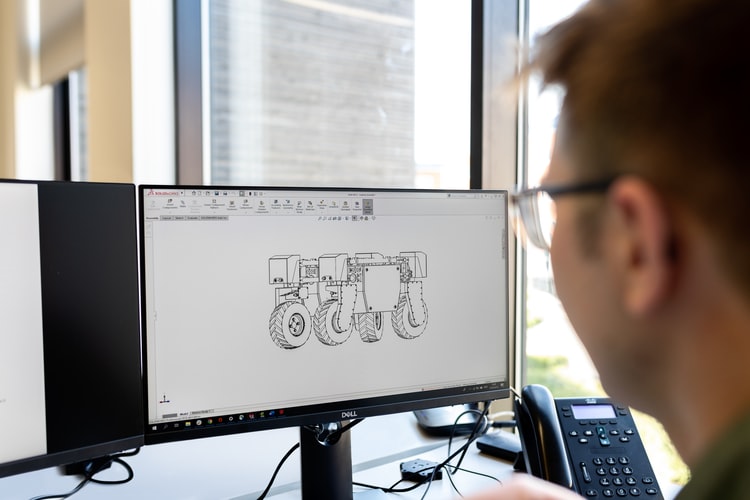

This is possible by using all the possible tools available, such as CNC machining machines, CAD software, computer numerical control (CNC) and computer controlled machining techniques. All these techniques enable engineers to achieve high quality in the manufacturing process, which is extremely important if you want your products to last for a long time.

Of course, it is also important for engineers to be able to ensure that the high quality products that they sell are durable and reliable as well. This means that they need to consider the material and the process in which the products are made, and try to find ways of increasing the level of quality and reliability in the manufacturing process.

What Can We Learn From These Processes?

Sometimes, engineers have to use certain machinery to do this, and in most cases, this will involve a process called roll-to-roll, where an engineer uses rollers in order to create prototypes and then checks whether the prototype has passed all the specifications that they have set for it.

So, is it really that important to use these techniques in order to ensure that your products are durable and reliable? Well, it certainly is! This is why objects and items going through precision engineering processes are rigorously tested. This is to ensure that there are no faults and that the equipment or items being produced can work effectively without becoming damaged or worn out.